Precision

Manufacturing,

Built to Last

Your Partner for High-Precision Batch Manufacturing. Industrial-grade quality with rapid turnaround times.

25M+ Parts Created

- 30-60 Minute quote response

- ±0.01-0.05mm Precision control

- ISO-certified Quality system

- Free Technical Support

Our Facilities

Advanced Manufacturing Hub

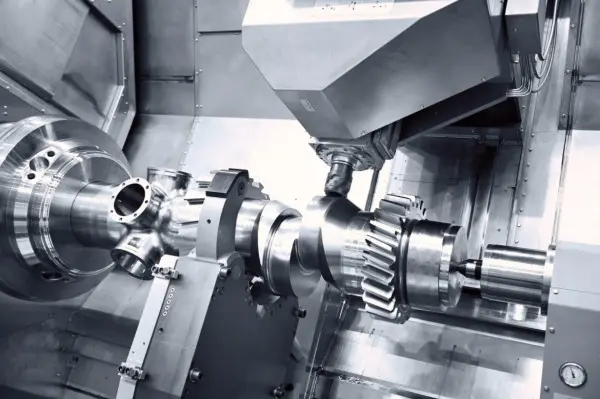

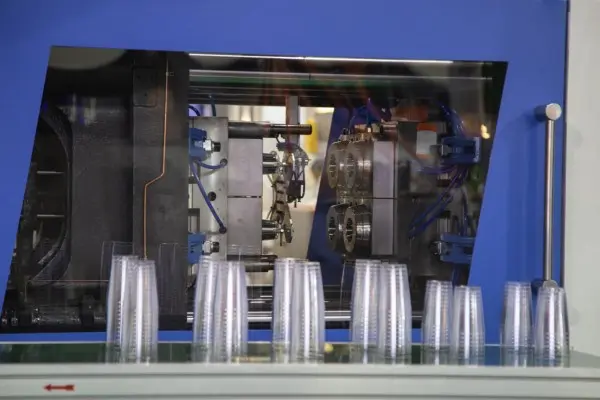

Located in Shenzhen's advanced manufacturing district, our 50,000 m² vertically integrated facility operates 8 specialized production shops and is equipped with 300+ advanced machines.

We support end-to-end manufacturing in one location, including CNC machining, precision injection molding, sheet metal fabrication, 3D printing, as well as in-house surface treatment and quality inspection lines.

Our Services

Everything You Need to Move from Design to Production

Need a custom solution?

Get Instant QuoteHow to Work With ApexBatch

A clear, guided process that takes you from design to delivery — without unnecessary complexity.

Submit Your Design

Upload your CAD files and basic requirements. Our team reviews your drawings, materials, tolerances, and application needs.

- STEP, IGES, STL

- PDF Drawings

- 3D Models

Engineering Review & Quotation

Within 24 hours, we provide a manufacturability review, process recommendations, pricing, and lead time options.

- Automated Pricing

- DFM Analysis

- Material Selection

Production & Quality Control

Once confirmed, we start production with controlled processes and in-process inspections to ensure every part meets specifications.

- CNC Machining

- Quality Control

- Progress Updates

Delivery & Ongoing Support

Parts are shipped with tracking and inspection records. Our team remains available for follow-up support and future production needs.

- CMM Inspection

- Quality Certs

- Fast Shipping

Why Engineers Choose ApexBatch

Comprehensive Free Services

Full-spectrum support including DFM analysis, process optimization, design validation, and quality inspection. Reduce trial costs with free engineering verification.

Get Free engineering review before production.

Upload Your DesignIndustries We Serve

Supporting medium-to-large batch production across industries with strict performance, compliance, and delivery requirements.

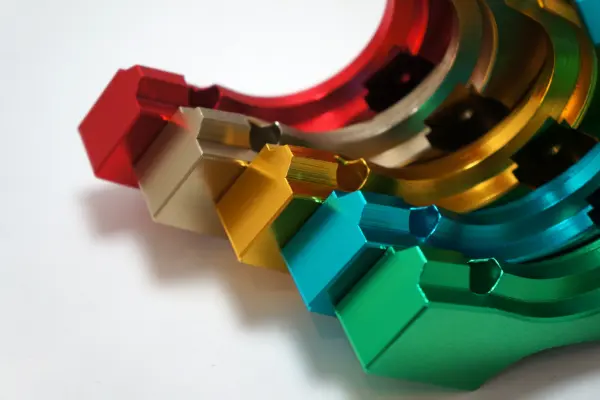

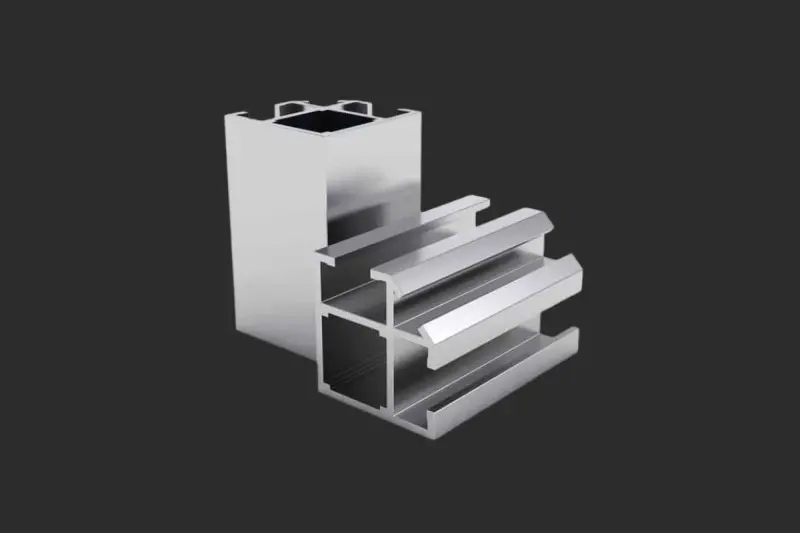

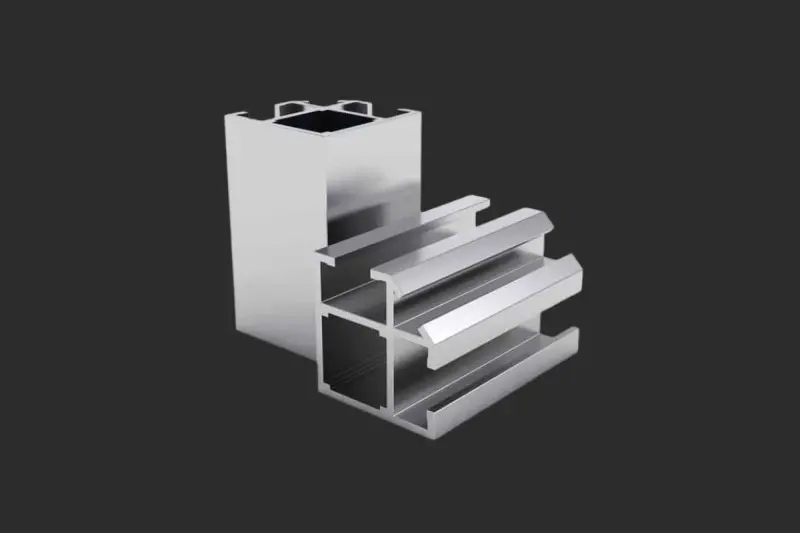

Excellent Parts We Made,

Built for Real Applications

CNC Machining

Die Casting

Extrusion

Sheet Metal

Injection Molding

CNC Machining

Die Casting

Extrusion

Sheet Metal

Injection Molding

Ready to experience precision engineering?

Get a Free QuoteYour Trust,

Verified by Data.

We exceed standards with rigorous testing and verification for real-world applications.

Zeiss CMM Verification

Every critical dimension verified by world-class metrology.

Dynamic IPQC

In-process quality control every 2 hours for consistency.

Full Documentation

Digital OQC, Material Certs, and DFM reports included.

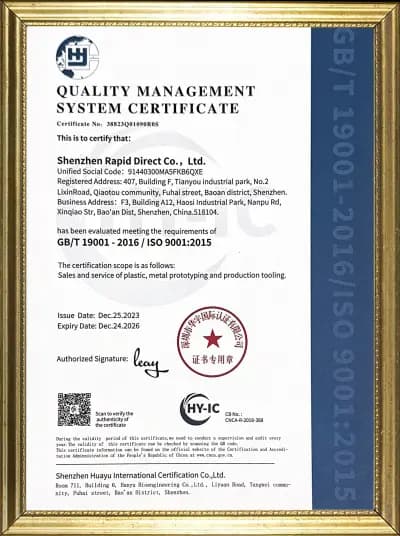

ISO Certified

ISO 9001:2015 & ISO 13485 & ISO 14001 standards backed.

Have Any Questions?

Find answers to common questions about our precision manufacturing services, quality standards, and production capabilities

We achieve tolerances as tight as ±0.01mm for CNC machining and ±0.05mm for standard parts. Our Zeiss CMM equipment verifies critical dimensions to ensure your specifications are met consistently across production runs.

Still Have Questions?

Our engineering team is ready to discuss your specific manufacturing requirements and provide tailored solutions for your project.